Be yourself; Everyone else is already taken.

— Oscar Wilde.

This is the first post on my new blog. I’m just getting this new blog going, so stay tuned for more. Subscribe below to get notified when I post new updates.

Be yourself; Everyone else is already taken.

— Oscar Wilde.

This is the first post on my new blog. I’m just getting this new blog going, so stay tuned for more. Subscribe below to get notified when I post new updates.

In honour of International Women’s day here at Machines Room I wanted to take a moment to celebrate some of the most influential women working in design, both now and in the past.

Too often women’s contribution to the field of design is overlooked. Even in today’s climate, a survey by the Design museum last year found women only ‘make up just 22 per cent of the design workforce, even though seven out of 10 students taking design at A level are women’.

I thought it would be a perfect opportunity to highlight the female designers that inspire me in the hope to spread the work of these amazing designers so they can inspire others. During my education in design I never had exposure to any female designers, they are so underrepresented within design education, and if we ever hope to encourage more women into the industry this needs to change. The list includes some of the ‘hidden’ women of Bauhaus and the 20th century and some contemporary designers changing the design landscape of today.

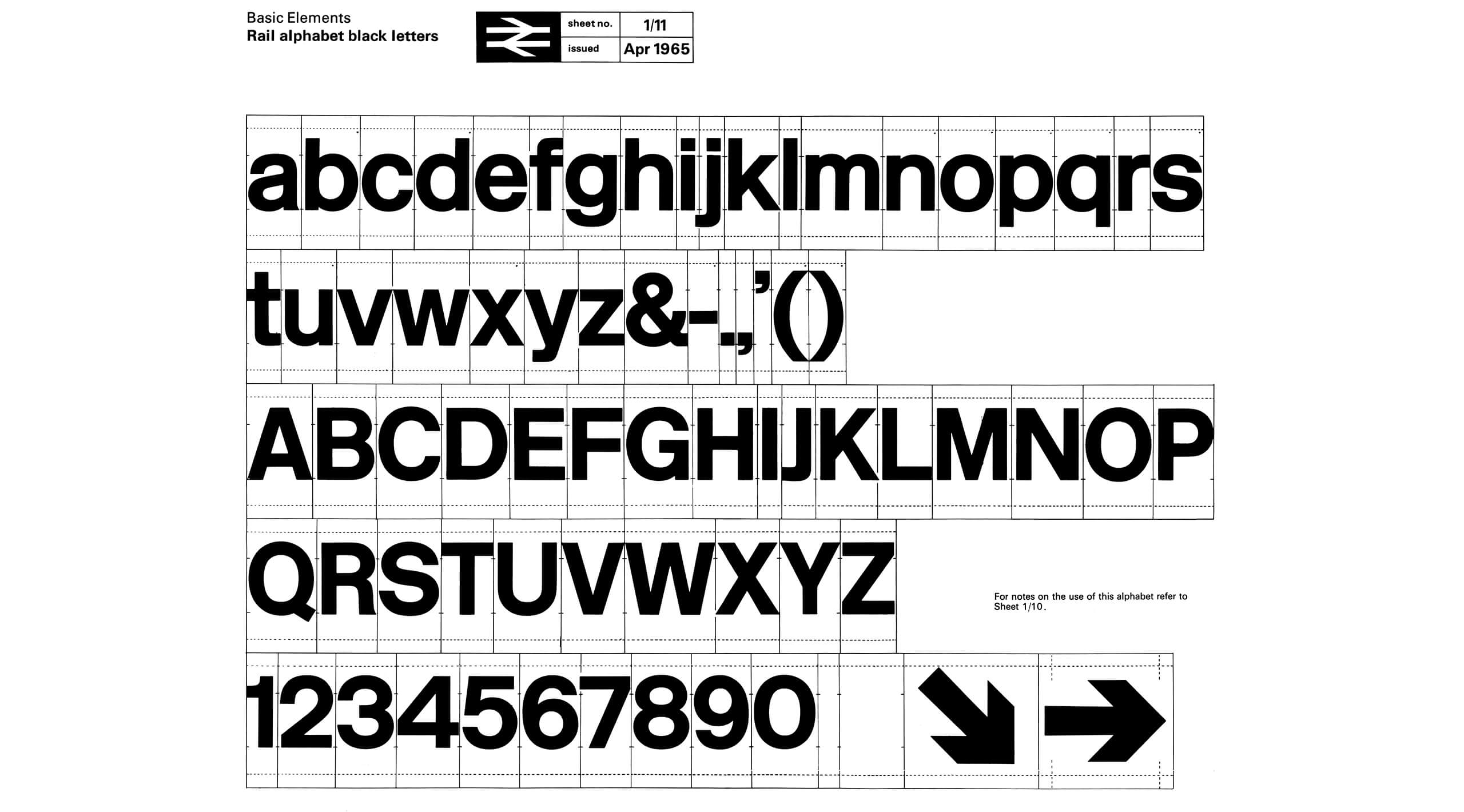

Almost everyone in the UK knows Margeret’s work even though they may not know her name. Alongside with colleague Jock Kinneir, she has designed many of the road signs that we are so familiar with. She started this work in 1957 yet recognition for her contribution to design only started to happen in 2015 after an appearance on Top Gear with a D&D President’s award and an OBE. You can still download some of the typefaces that she designed today, my favourite, of course, being the one she designed for the British railway system in 1965, a beautifully simple and clear sans serif, that was also once used for the NHS. Her others include the Road sign typeface we are so familiar with, the Tyne and Wear metro font and the seperate Motorway type that is used to show junction names.

Charlotte’s work is perhaps most recognised from gracing the interiors of Le Corbusier’s modernist structures. Initially when she applied to work in Le Corbusier’s studio in 1927 she was famously rejected with the phrase “”We don’t embroider cushions here.”

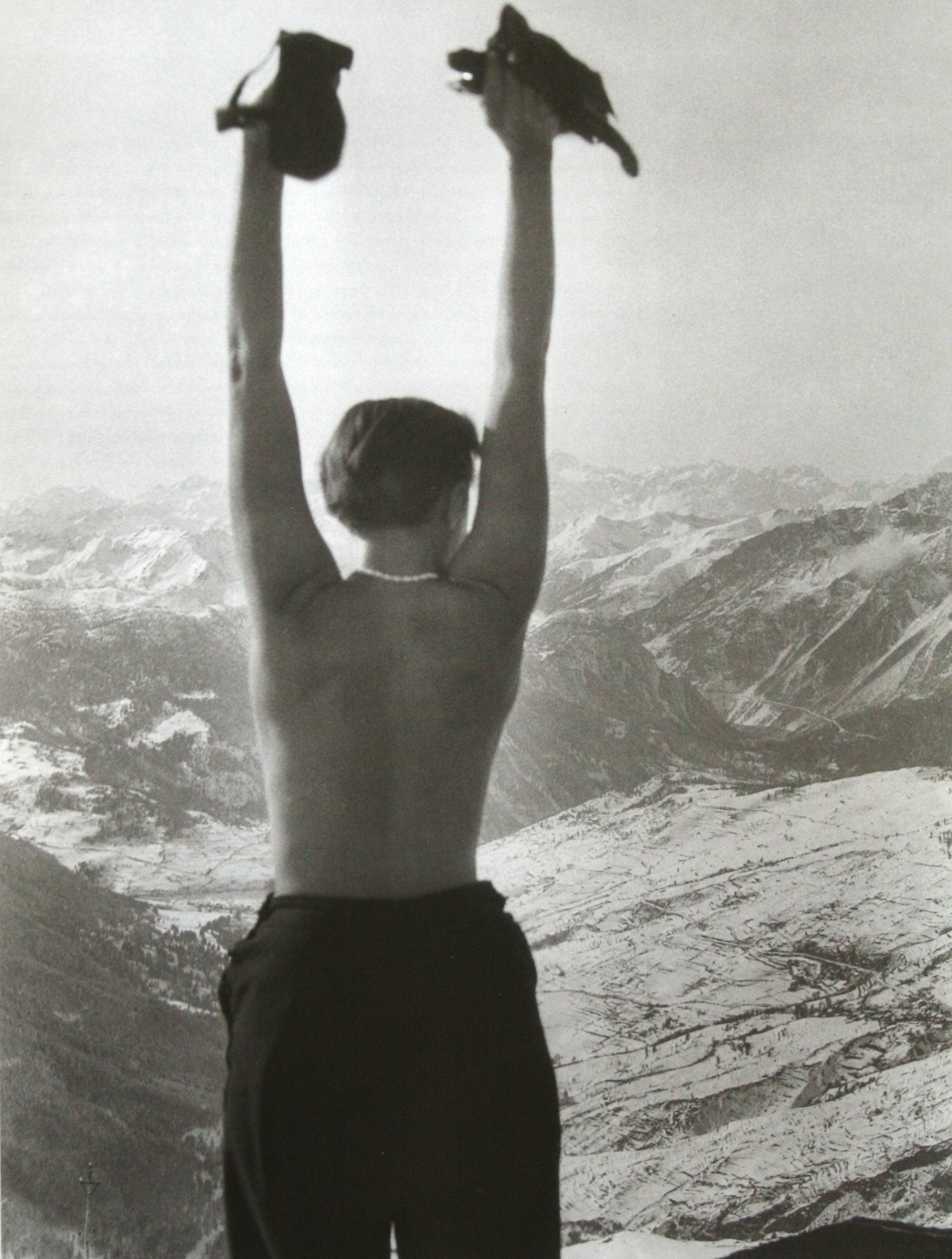

A month later after he visited her exhibition, impressed by her ‘Nuage Bookshelf’ (pictured) he offered her a very sought after job in the male dominated furniture design. She designed the iconic B301 reclining chair, the B306 chaise longue and the LC2 Grand Confort armchair for him. She went on to furnish some of Corbusier’s most famous buildings such as the Unité d’habitation as well as designing her own structures, from the league of nations in Geneva to entire ski resorts like Les Arcs later in her career.

Eileen cannot be categorised, starting off as an artist at the Slade school of art she went on to train in the Japanese art of lacquered screens influencing her style, before delving into furniture, lighting, textiles and architecture. Whatever form her work took it always echoed a clean modernist aesthetic with a love of luxurious material and decorative finishes.

Similarly to Perriand she worked and exhibited alongside those who we perceive as the historic leaders if the modernist movement like Marcel Breuer and Le Corbusier. Her perhaps most famous tubular steel furniture was exhibited well before Corbusier adopted the style himself.

It wouldn’t be a list of influential women designers without Ray Eames, of course. Her design practice alongside husband Charles has granted her visibility in a way that many of these other designers of her time didn’t experience. Her work with him ranged from designs for furniture, houses, monuments, exhibitions, experimental films – and even toys.

Perhaps more important then the designs themselves are her and Charles’ contribution to the development of new materials and processes that have transformed design. The most iconic being their steam bent ply technique, now seen in chairs everywhere. It was initially developed for leg splints during WWII. The image below shows a sculpture Ray made to accompany the splint, this perfectly symbolises their commitment to beauty in the everyday.

.jpg)

Seetal represents a new kind of designer, one keenly needed for our changing industry. Author of ‘Why Materials Matter’ Seetal’s practice as a designer is completely focused on the materials that make up our world and the materials that can change our future. If our rate of consumption continues we must find alternatives to the materials we use from day to day. But her material research is more than just finding alternatives to useful consumer products, it’s about completely new materials that may not have a clear use but aesthetically inspire new possibilities for the design process. Just as Eames did with the plywood splint, Seetal has the possibility to change the materials and processes we use, shifting the landscape of design. She runs Ma-tt-er a material research studio who’s consultancy work help brands and products re-think their material applications and processes in a more sustainable way.

French designer of experiences, Nelly Ben Hayoun’s influence stretches globally. Recently announced as Advisor to the United Nations she also serves on the Advisory Council of METI (Messaging Extraterrestrial Intelligence), is head of experiences at WeTransfer, is a member of the International Astronautical Federation, Space Outreach and Education committee. She’s also the director of The University of the Underground, a tuition-free postgraduate university as well as lecturing at companies and universities across the world.

Her work defies characteristic even in today’s post disciplinary landscape. She started by collaborating with scientists and engineers to devise events and experiences, yet this collaborative approach has now extended to brands, philosophers, musicians and politicians. Representing the future role of design in shaping how we experience the world. Her secret? Revelling in speculation, her 2015 film Disaster Playground is based on an investigation of emergency procedures for disasters such as earth-bound rogue asteroids. Described by one reviewer as “Dr. Strangelove meets This Is Spinal Tap.”.

OOMK otherwise known as ‘One of My Kind’ is actually a collective of three inspiring women, Rose Nordin, Sofia Niazi and Heiba Lamara. They make, publish and distribute books and printed works. They say their zine focuses on ‘the imaginations, creativity and spirituality of women’ giving amazing up and coming women the exposure they deserve whilst also exploring the female experience around a variety of themes from ‘topics of faith, activism and identity’.

On top of this, they run one of the UK’s largest annual independent publishing fairs, founded and run a community Risograph printing press in East London and regularly work with galleries, museums, educational institutions and self-organised groups to deliver workshops and produce collaborative publications. The visual style is distinctive and imaginative and is what drew me to their work at zine fairs years ago, but it’s their commitment to changing the design industry by supporting and giving a platform to other female creatives that made me a long term fan.

Kathrin Bohm describes herself as an artist yet her commitment to shaping the Natural and Public realm for all people echoes the role of a designer. Kathrin is a founding member of the international artist group Myvillages, the artist initiative Keep it Complex – Make it Clear, art and architecture collective Public Works, and the Centre for Plausible Economies.

Her work with Public Works s address the question of how the public realm is shaped by its various users and how existing dynamics can inform further proposals. Their outputs are not limited to buildings or art objects. They include discursive events, research, campaigns, urban strategies, participatory art and architecture across all scales.

Kathrin is also an author of many publications for public works, her most recent publication contribution in ‘The Rural’ ‘investigates the complex relationship between the urban, the rural, and contemporary cultural production.’ A designer representing the future of design strategy for engaging with rural communities and the natural world.

This is an example post, originally published as part of Blogging University. Enroll in one of our ten programs, and start your blog right.

You’re going to publish a post today. Don’t worry about how your blog looks. Don’t worry if you haven’t given it a name yet, or you’re feeling overwhelmed. Just click the “New Post” button, and tell us why you’re here.

Why do this?

The post can be short or long, a personal intro to your life or a bloggy mission statement, a manifesto for the future or a simple outline of your the types of things you hope to publish.

To help you get started, here are a few questions:

You’re not locked into any of this; one of the wonderful things about blogs is how they constantly evolve as we learn, grow, and interact with one another — but it’s good to know where and why you started, and articulating your goals may just give you a few other post ideas.

Can’t think how to get started? Just write the first thing that pops into your head. Anne Lamott, author of a book on writing we love, says that you need to give yourself permission to write a “crappy first draft”. Anne makes a great point — just start writing, and worry about editing it later.

When you’re ready to publish, give your post three to five tags that describe your blog’s focus — writing, photography, fiction, parenting, food, cars, movies, sports, whatever. These tags will help others who care about your topics find you in the Reader. Make sure one of the tags is “zerotohero,” so other new bloggers can find you, too.

We’re changing it up at Machines Room! Starting Wednesday 27th November we will launch our new membership scheme and our revamped fablab at Containerville. We’ve downsized to one container to focus on digital fabrication, and we’ll also have 3 desks available for rent.

To sign up to our new streamlined Fabman booking system, please complete this google form, and we’ll create a new account for you. We will be cancelling all membership on our current system, so if you are due a membership or booking refund, let us know at info@machinesroom.org. Please note that we are also re-working the pricing structure for membership and bookings. Becoming a member is currently FREE and we’ll only charge machine time but this might change in January 2020.

We’d like to introduce Julien Vaissieres, the new manager of Machines Room. Julien is a long-time collaborator with Machines Room, having joined machines room in 2016 to start his 3d printing factory Batch.works. When we moved, Batch.works came with us, becoming our neighbour at Containerville, so he will already be a friendly face to many of you.

Our workbench tools, power tools, and our plastic kitchen are now at Greenlab.

Re:flex is a team working to make shape-memory materials accessible. We developed our own composite material that can change its shape with heat and are exploring its applications in an everyday context – beyond the traditionally technical fields that shape-memory materials are normally used in.

What brought you to Machines Room?

After graduating we needed a space to continue working on re:flex. We had a few friends who had used the space as professional members (Good Waste and Ned Quiney from Cohort), and it seemed to be the first name mentioned when asking people about workshops in London. We needed a workspace we could afford, and that had access to a variety of tools including digital machines such as 3D printers, laser cutters, woodworking tools and a space to work with plastics. Machines Room fit the bill perfectly.

Tell us a bit about your backgrounds, your practice and areas of interest?

The three of us met doing the Innovation Design Engineering Masters at the RCA and Imperial. We came from pretty different backgrounds – Benton did philosophy and music, Pierre was an electrical engineer and Karlijn was a product designer with a focus on materials. Individually, our practices are quite divergent. However, as a collective we share a common goal in making new technological developments accessible, bridging the gap between research and everyday implementation.

Can you tell us about what you’ve been working on?

At the Machines Room, we’ve been working on new pieces for London Design Festival and Dutch Design Week. We’ve been using the space to do both show design as well as making more material samples.

What’s your favourite part about being at Machines Room?

We really like being able to work at our own convenience at weird hours of the day. The Machines Room also have a great selection of tools for both digital and physical making. It’s been really handy having access to the variety of machines in the space, as our work requires both digital machines, as well as traditional tools.

What’s next?

Re:flex is showing at the VEEM at Dutch Design Week from the 19th to the 27th of October. Come say hi if you’re about!

GoodWaste is a new design studio working on projects that create social and environmental good by reconsidering how objects are made. We research localities, investigate material flows, and experiment through making. We use objects as commentators and communicators for bigger ideas around sustainability.

What brought you to Machines Room?

We were introduced to Machines Room by our tutor while at the RCA and Ewan had been involved in a design sprint hosted at Machines Room last year.

Tell us a bit about your backgrounds?

We are all from product/industrial design or design engineering backgrounds, and we all worked for design studios before starting on the Design Products programme at the RCA, where we met each other. Especially since starting the RCA, each of us has become dedicated to sustainable design, in one form or another.

What have you been working on?

After we graduated from RCA last July, we became members of Machines Room to run a small batch production of our MA collection of homeware and furniture made from waste collected in Park Royal. The collection is now on sale at Selfridges, as part of its Bright New Things campaign.

Best Bits of Machines Room?

Our favourite part about being at Machines Room was being able to work anytime we wanted, as it’s 24h access! The verity of machines we had access to was great and let us prototype designs super fast. Last but definitely not least the Machines Room community practitioners and staff are all super helpful and were a great encouragement when we were running out of steam!

What’s next?

At the moment we are establishing GoodWaste as a brand and studio, looking for more commissions and collaborators that share our vision for sustainability and design. We will also be running a series of workshops to teach participants about circular design and hands-on making skills to help spread the word and interest in how we approach sustainable design.

We are once again opening our doors for London Design Festival this year. We will be open for the public to look around machines room and running some exhibitions and workshops too!

Cohort Residency Exhibition – Private View 20th of September

Since the start of August, Machines Room has been home to our new Cohort micro-residency group. Three graduates from the Royal College of Art have been developing and expanding their practice using our machines ready to exhibit at the Festival. Check out who they are below.

Anya Muangkote

I’m a multidisciplinary designer, aiming to make sustainability appealing. My focus is on designing for circular economy principles — design for biodegradability; recyclability; produce more locally and without toxicity. I’m drawn to the topic of future materials and food, distributed systems and renewable energy. My ongoing project is looking at agar-based bioplastic material properties and how it could be applied in a real-world context.

Website: https://anyamuangkote.info

Instagram: @anyamuangkote

Twitter: @anyamuangkote

Ned Quiney

I am interested in efficiency and viability; both of the things we make, and the tools and processes we utilise – and design for. But more than what is optimal now, I like to think about what could be possible, if those tools and processes were to be optimised further. By looking downstream into the essence of how we create things in the world today, and implementing real honest change there, I believe we have the most power to shape the future into something that works better for all of us.

DMP (Digitally Moulded Plywood) is an experimental process of forming curved plywood, optimised for distributed manufacturing. By using a universal aligning spine and precisely machined wood instead of a mould to laminate the wood, new possibilities emerge to democratise the production of curved plywood; enabling a new generation of designers, makers, and the curious, to create with this high-strength, beautiful and natural material.

website: https://nedquiney.myportfolio.com

Jihee Moon

Jihee studied metal crafts and industrial design at the RCA, designing new experiences by stimulating people’s emotions with various materials and experiments. I aim to convey my thinking and sensibility about general problems and issues to people and link the existence that is me, others, and space, with the product as the medium.

My design puts forward solutions for general problems and issues that engender as contemporary people lead their lives in the organisation that is society. I continue to research for my design with the aim of providing solutions that are based on the fundamental five senses and sensibility intrinsic to human nature, and respect for life.

Instagram: @moonji123

Website: www.air-it-yourself.com

Light_00 Workshop and Launch

Exclusively for the London Design Festival, we will be launching the versions lamp. Designed by Milo Mcgloughling Greening and developed by a host of designers with Other Today this Lamp is completely distributable, designed to be made with just a few broomsticks, 3d printed parts and a bulb. Learn how to build your own in our workshops running throughout the festival. The Lamps will also be available to purchase as a kit or pre-assembled from Machines Room during the festival.

Our lovely friends at Tala have donated some of their amazing LED glass bulbs which will be included in the ticket for the workshop along with everything else you need. It will be run by Machines Room with Other Today. Milo Mcloughlin-Greening first developed this lamp at our Distributed Design Market Platform sprint for the London Design Festival in 2018, which was also supported by Tala.

This year a new group of designers came to Machines Room for another design sprint to develop the original Lamp_00 design to be more distributable, refining its customizability with different broom handles and making their open instructional video to help others make it.

Since then it has been made, remade and remixed, it has been tested and produced worldwide with makers in Kenya, Ghana and Nepal all making their own versions using locally sourced materials, one of my favourite’s hacks the simple design for a mobile shooting rig. http://www.diale.org/Light_00.html

The workshop will be running for 9 days throughout the festival from the 14th to the 22nd of September, you can book your tickets through the eventbrite here:

In this workshop you will be taught some essential DIY skills safely such as; drilling, wiring up plugs and lights, sanding and finishing to high quality, accurately measuring and sawing. you will also learn how to 3D print and pick out the colours of the parts you would like to use.

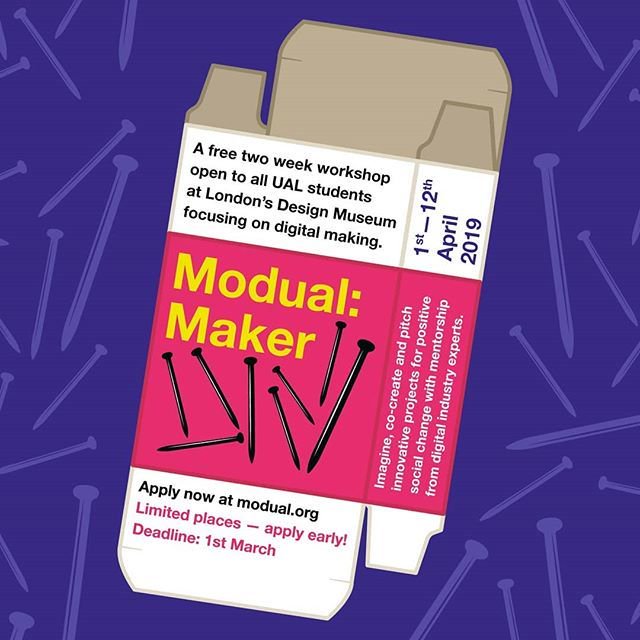

In April we hosted the making sessions of the innovative arts education program ModUAL run by Fred Deakin with Other Today and the Design Museum.

ModUAL brings students from a range of disciplines, across UAL’s different campuses together for an intense 2-week design sprint aided by industry moguls.

With the constraints of a traditional educational institution where each discipline has its own assessments, curriculum, teachers and budgets, many talk of multidisciplinary education but few actually put it into practice. ModUAL remedies this, a voluntary module for all at UAL whether BA or MA, studying game design or fine art.

This is such an important process to involve the students in for preparing for the industry. In all industries you will need to work with people from different backgrounds with different roles, learning what they are and how to put everyone’s expertise to best use will see you far.

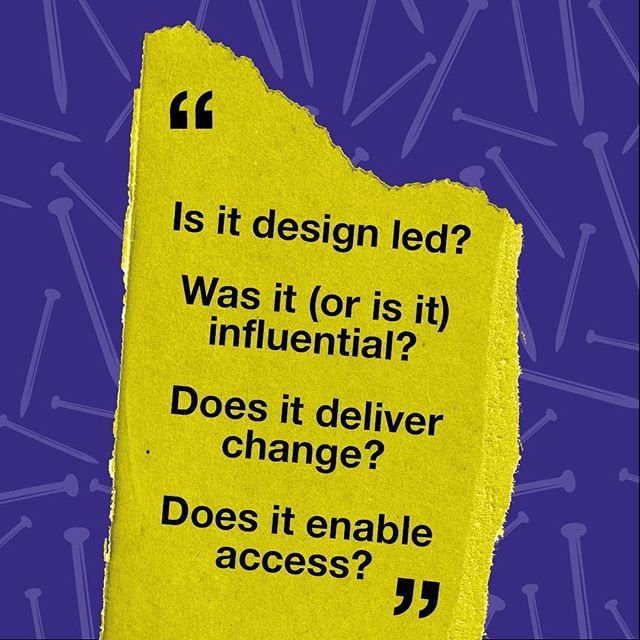

ModUAL tasks these creative multidisciplinary teams with an extremely short deadline. They are given just two weeks to design, prototype, make and brand a product before pitching this to industry giants Sevra Davies and Tom Wilson, both from the Design Museum. No small task.

“What we need is a bridge into the industry. Being the maker of a wide range of creative projects over the past 25 years has led me to believe that the best work is created by multi-disciplinary teams working collaboratively to tight deadlines. This should come as no surprise to anyone. Whether it’s clients, colleagues or bosses, in the real world we are not the sole authors of our work but join with others to deliver what we’re unable to alone.”

– Fred Deakin

ModUAL draws on digital tools to make this happen, with Skype tutorials and slack to keep the conversation open between students and mentors anytime, anywhere, whether in the workshop, at the printers or on the bus. Enabling students to communicate and seamlessly merge on and offline collaboration, outside the classroom.

One of my favourite products was Pluna, a travelling pot which will always bring your plant closer to the sun. Others include plate mates, a jigsaw like modular lunchbox collection to encourage social eating and sharing food. Revive pushed our 3d printer to t’s limit 3d printing with thermoplastic filament (super cool and worth a go if you’re interested – Prusa printer still only £5 ph).

Some of the students were completely at home in machines room, coming from a hands-on practice or construction background, for others, it was their first time using machines and making something from scratch. Many students underestimated what was involved in taking these ideas to prototype in such a short time but through teamwork, all achieved amazing results!

Previous ModUAL collaborators include Kickstarter, UsTwo, Mother, Makerversity, Somerset House, British Council, Screen Skills, Glasgow SoA, Falmouth SoA and Manchester SoA.

If we want more students to take creative subjects such as design we need to do more to prepare them for industry and show them the value in it. Too often the question of making money is avoided in the arts, seen as distasteful as it must only be about creative expression. ModUAL shows the two can easily go hand in hand with industry style briefs and timelines that push them to the creative limits and connects them with experts in the field.

In July they’ve done this all over again in Shanghai, and got a collaboration with Kickstarter and Glasgow school of art in August. It can work all over the world, creating opportunities for the next generation of designers and artists.

At the end of March, we ran our first workshop in collaboration with the Science Museum and the Worshipful Company of Scientific Instrument Makers. This was the first ‘making’ step in a long collaboration between the two historic Institutions. Machines Room will be helping them make their Scientific Instruments in a Fab lab setting using modern distributable design techniques.

This first workshop was simply to introduce the participants to the idea of a maker-space, to train them on our machines and software and to start to make playfully and collaboratively as a group.

Many of the participants weren’t familiar with Maker spaces and the type of experimental making we can facilitate, so the workshop was designed to introduce them to the making practice we can offer at Machines Room.

We started with a pair of movable walls we have at Machines Room which have furniture bolt plugs set into the wood at regular intervals. The same system that all the furniture at Machines room is built on. These walls acted as the base for the makers to build a vertical mechanism system on.

We used a website called Gear Generator to design gears to mount to the wall. These drawings could then be adapted in a vector program and cut accurately on the laser cutter. We also experimented with using our workbench tools to design and cut cams to change the rotational force into a vertical force. The makers then took this and ran with this, from a maltese cross, made with a ginger biscuit, to a pulley crane prototype.

This was just the start of the making section of this project and the makers will return soon to start to use what we learnt in the workshop to start constructing replica’s of 18th-century scientific instruments using distributable design.

This relationship between scientific instruments and DIY making has a long history. At the start of the Industrial Revolution, it appeared that most scientific instruments were made and sold in London. These were made, not by corporations, but by creative, scientifically minded, makers. Often making use and re-use of the materials around them in the city. A lot of the scientific breakthroughs in design and engineering of the 18th century started as inventions made in peoples homes by amateurs. These ‘amateurs’ were so excited by these scientific and technological developments that they sought to disseminate this knowledge by writing instruction manuals and books so that anyone else could make them too.

Now, hundreds of years on, we are seeing a shift back to this DIY localised manufacture. With the technological development of digital manufacturing, machines are becoming available to anyone to use and then sharing of information and designs online fuelling the ‘new industrial revolution’ as Chris Anderson puts it in his book ‘Makers’. Production and design is moving out of the factory and back into the home or rather into the maker space.

A great example of this is the centrifuge. The centrifuge creates rotation around a fixed axis and the acceleration of this allows the denser particles to move towards the edge of the container and separate from a solution. This invention revolutionised chemical innovation with the ability to separate particles down to a nanoscale to aid research, analysis and diagnosis, it is also used in everything from G force simulators for space (or at Disney World) to your spin cycle in your washing machine!

The invention of this scientific instrument started as an experiment by a farmer to make the machine to separate cream from milk in the 19th century but was soon adopted by the scientific community.

Many of the centrifuges that followed developed by institutions and corporations are large, expensive, electrically powered machines. Fast forward to five years ago and makers are starting to reimagine the centrifuge in new ways, from the ‘dremelfuge’ using a Dremel or cordless drill and a 3d printed part to the revolutionary ‘paperfuge’ just made with a bit of paper and an elastic band.

This ‘amateur’ invention took the centrifuge from the oversized heavy machine costing thousands of pounds to something that can be made by anyone, anywhere in the world, costing just 20p.

For me, this is the possibility that makerspaces and a return to DIY production pose to the scientific community, an opportunity to redesign not for mass production but for mass invention.

Here at Machines Room, we’ve had our fair share of instrument inventions from the different resident makers who have shared their journey with us. One of these was Kniterate, a machine designed for the digital manufacture of knitted products, taking the iconic loom of the industrial revolution and giving it a 21st-century digital design makeover! Since launching their Kickstarter with us they have since moved to Makerversity to continue to push their machine further when I visited them last they had just taught their machine to start knitting complex stitch styles such as the cable knit and lace knitting.

I found it so interesting to learn about the history of the Worshipful Company of Scientific Makers in London and what it means to be a Scientific Instrument Maker today from talking to the young makers taking part. Many working as Scientific Instrument Makers now didn’t have a hand in the construction of their machines as it was often outsourced. Through being at Machines Room and introducing some of them to makerspaces I hope will in some way inspire these talented scientific Instrument makers to get tinkering themselves.